|

|

|

The tachometer was added to the power supply as an afterthought. When the motor of the power supply gets used for power generation experiments the tachometer will be useful to use to determine the most efficient operating point. There will be a study made later of the alternator to determine its maximum output abilities also. It is important to know the exact speed of operation for that study. At this point in time the tachometer is merely 'along for the ride'. All the data recorded from the supply experiments will include the tachometer speeds so that the experiments do not have to be repeated later for the generation experiments.

The tachometer is made from an automotive speedometer. The RPM range that it works at is exactly right for the RPM range that an inductive squirrel cage motor may work at. Even the direction of rotation is correct. The cable from the speedometer is simply plugged into the end of the motor shaft using two rubber grommets as slip fit connections.

Although the speedometer is capable of giving a very accurate reading it has to be handled in special ways. The needle is not balanced. The speedometer has to be held level or it will drift about 5 to 10 miles per hour for even a slight tilt. It is also very temperature sensitive. It has to be operated for several minutes ahead of time to allow it to stabilize internally. The error due to that is about 3 miles per hour.

From here on out the device will be referred to as a tachometer instead of a speedometer. What follows is a pictorial version of the construction. In brief, chop away everything that doesn't look like a tachometer, make a stand & a dial face, and plug it into the motor.

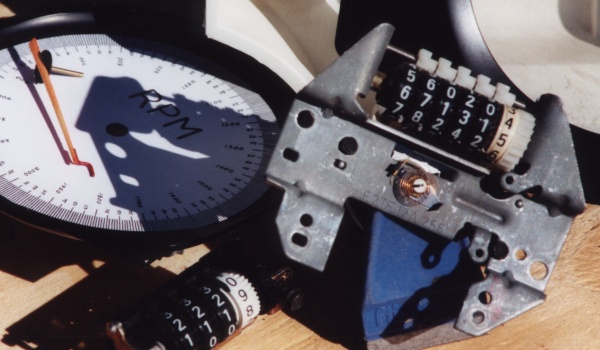

The above left side picture shows all the parts of the original instrument panel after being chopped up. The original range of the speedometer was 85 MPH. The center picture shows the core of the unit after removing the trip meter and the worm drive gears. There is a tiny spring with an adjustment in the center of the unit. Turn the adjustment counter clockwise about 20 degrees. That amount would correspond to about 10 MPH on the scale. Do not adjust it again.

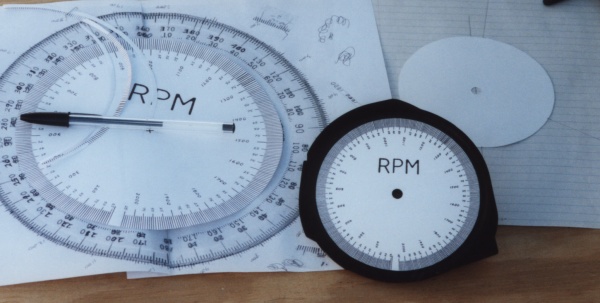

The right side picture shows the finished tachometer dial and some of the paperwork that went into it. In that picture you see a blank circle and an enlarged dial. The enlarged dial is the rough draft of the finished dial. The blank circle is the calibration dial. The blank circle has two tiny marks on it. Those two marks were made at the high and low speeds of the motor in operation. Those two marks are the references on which the entire scale is based. The high speed mark is 1790 RPM. That is how fast the motor spins on high speed with no load. The other mark is 1130 RPM. That is how fast the motor spins at low speed with no load.

Measure the angle between those two marks. That angle will be equal to a span of 660 RPM (1790-1130). In this case the angle was 108 degrees. From that you know that the needle moves 6.11 RPM per degree. It was determined that the smallest markings that would be practical to make with a ball point ink pen would be about 1/16" apart. That corresponded to 1 mark for each 5 RPM at a spacing of 0.818 degrees.

With that information five sheets of calculations were done to find the exact number of degrees for each mark to be made on the dial. To produce the rough draft begin by coping a 360 degree protractor onto a sheet of paper. Two 180 degree protractor copies were used in this example. Draw the dial onto the protractor and then reduce it to the right size to fit the tachometer. It will take a lot of time and patience to do this. The finished dial is printed out on card stock and taped to the face of the tachometer using double sided tape.

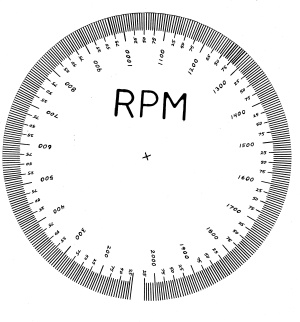

Tachometer dial

To plug the tachometer cable into the motor axel is surprisingly simple. The bracket used must be very rigid. It must not be springy in any way. The end of the cable housing merely slips into a hole of similar size drilled into a wood block. The alignment should be fairly good. The tip of the cable slips into two rubber grommets that are glued into the end of the pulley using Goop adhesive. A slight bit of spit is used as a lubricant for insertion. The cable itself needs to be disassembled, cleaned and lubricated using a light oil.

Details of the cable holder bracket and the grommet connections

The legs for the tachometer can be made from just about anything. In this case they are made from the remains of a childrens toy which was formerly a swing set for 'Muppets'. The tachometer is setting on the top using silicon additions. To make them, cover the stand with plastic wrap and then shape the additions to fit. The tachometer assembly may then be disassembled easily.